F&B Logistics -how to improve the procurement process?

F&B Logistics, if a question is asked on how to improve the procurement process in F&B, it will definitely circle around technology. In fact, the F&B procurement platform is the focus of all such discussion.

In this article (and through some images), we hope to showcase the "weak link" in the procurement process and a re-look into your procurement guidelines.

It is a practice and routine that need to be followed in order to ensure your supply and your product integrity.

F&B Logistics common practice

Practice 1: Receiving in person.

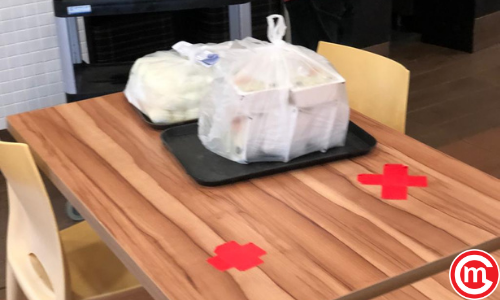

Common sense will tell you that there are 101 things that can go wrong in this particular image. And yet, it is a common practice.

Supplier leaving the products outside of the stall/shops/restaurants before the arrival of the F&B operator. There is no proper receiving and signing off the document and in many cases, the products can be easily tampered with by pest (birds).

How to improve the procurement process in F&B?

Practice 2: Rotate and have an alternative supplier

The fact is, it is cheaper when the whole area order from the same supplier and usually it is a trustworthy supplier. But, if you remembered what happened during 2020 COVID, relying on just one supplier can have a negative impact when anything happened to this vendor.

Moreover, you are also at the mercy of collective delivery (e.g. we are delivering to all outlets at this timing). In this case, it is obvious that the supply comes from 1 wholesaler, so the first thing that you as an owner/operator need to do is ensure that they deliver to you in person and you receive and inspect the goods.

Examples of procurement guideline

There are many examples of good procurement guidelines to be included when planning F&B, here we will state one, we felt is more important - SPS (Standard Purchase Specifications).

In the image above, the vegetables come in almost original format. E.g. you need x number of carrots, x number of carrots is packed.

If you have seen the stall (it is inside a food court), first, it has an impact on your E.O.Q (economic ordering quantity) due to the size of the stall and the shape of the produce.

The operator can specified that it comes sliced and vacuum packed. This will reduce the size, allows easy storage and allows the owner to have a document to refer to when it comes to receiving the product**

**In the case above, the owner can complain about blemishes on the carrots which the supplier can claim is the norm.

SPS also ensure that the image below WILL not happen. The chill product is delivered at ambience temperature. Imagine paying top dollars for quality products but only to receive it with bacteria multiplying inside!

The above are some thoughts from Ebenezer Heng, from the many observations and practices that are not in line with some recommended standards which he worry might comprise the integrity of F&B owners' supply.

If you like to look for articles similar to F&B logistics, check out our home page or drop us a line below for a chat.

Questions about Coffee

Questions about coffee? Have it answered by the professionals. Examples of some questions:

What are the considerations for an office coffee station?

What are the essential V60 Coffee Brewing tools?

Non coffee (but important to coffee) question: What is whole milk?

Featured coffee brewing method: How to prepare V60 Coffee?

Previously: Making Coffee with a Coffee Sock.

Recent Articles

-

How to Do Menu Engineering: Complete Guide to Restaurant Profitability

Sep 27, 24 03:09 AM

Learn how to do menu engineering to boost your restaurant’s profitability. Discover strategies for menu design, pricing, and maximizing profitability. -

Tim Hortons Singapore is a Canadian Coffee Chain?

Nov 16, 23 09:00 AM

Do you know that Tim Hortons Singapore is a Canadian Coffee Chain? Apparently only 46% knows that in our IG poll! -

Coffee report on WMF Coffee Machine Brand in Singapore

Oct 11, 23 03:45 AM

Coffee report on WMF Coffee Machine Brand in Singapore

Featured: Office Coffee Machines

Follow Oncoffeemakers.com's board Office Coffee Machines | Singapore on Pinterest.Do check out other cool boards such as the one all on how to make coffee and drip coffee.

Food and Beverage (F&B) Articles

Sustainability Practices in Food Service

3 Free Restaurant Marketing Ideas

Singapore Cafes Reviews -Can they be Trusted?

Location, location, location might be a myth!

Walmart and Walter -The Power of Social Media!

Importance of value pricing for Cafes In Singapore

Why Nescafe is still the Largest Roaster in the World?

Everyone likes Starbucks -here's why

Is your Cafe location an asset or a liability?

Location myopia: why good anchor tenant might not be good?

Measuring the Location attractiveness index.

Social Media Crisis Management for Cafes in Singapore